Editor’s Note: This copy is presented unedited, as written by Mr. Kahn, who is pictured above in the early 1950s. You’ll note that he’s a very good writer, with a clean, direct style. And, during the 1980s, E-V was shortened to EV.

Lou Burroughs and I formed a partnership on September 1, 1927 to service radio receivers. Both of us were in our early twenties and had been radio experimenters for a number of years. The invested capital was $30.00 and a second-hand car.

The firm prospered and within a year was the largest radio service shop in South Bend, Indiana. In addition, we had begun the retailing of radio equipment. The depression all but wiped us out. We found ourselves insolvent to the extent of $5,000. To survive and pay our creditors, we began work in the audio field and liquidated the remnants of the service and retail business.

The first product was a portable public address system, the first, to our knowledge, ever to be built, and was sold to Knute Rockne of Notre Dame for coaching from a tower. He named it his “Electric Voice.” On July 1, 1930, we incorporated and adopted the name “Electro-Voice.”

The first block in this new business was the poor quality and high prices of available microphones. Sensing an opportunity, we purchased a lathe and drill press and began making them at the rate of one a week (last month we made 20,000).

Burroughs withdrew and I assumed his obligations and stock. By 1933 all debts of the defunct business were paid in full by the new company. Out of debt, earnings were retained and by 1936 twenty people were employed. Lou Burroughs returned as chief engineer and E-V had already begun to make significant contributions to the industry.

In 1941, restrictions were placed on civilian goods and we had no contracts. Intensive work was done on a differential noise-canceling microphone. So radical in conception, we met with resistance by most government laboratories. Persisting, because we believed in it, we finally brought it to the attention of the right people. It was quickly standardized for all ground forces and Marine Corps.

We licensed the U.S. Government, royalty-free, and within a year were producing 2,500 a day. Our Army-Navy “E” was among the first in the area and industry to be awarded. Relations with the government with regard to quality, delivery, price, renegotiation and termination were harmonious.

By 1946, we began a new era. New facilities were acquired and expanded engineering began. In 1948, we began production of phonograph pick-up cartridges, which was immediately successful. In 1950, we produced the first automatic TV booster which sold in substantial quantities.

Also in 1950, we laid the groundwork for our present loudspeaker line. This timing proved to be right for our tooling, designs and distribution was set up when the expanding market developed in 1952.

Microphones, Broadcast and Telecast

We have grown, through the years, to be, we believe, the largest producer of microphones in the world (no official statistics are available). Our line is broad and covers most types that are used in all services.

For the past two years, we have been quite successful in breaking into the broadcast and telecast industry. All major networks, except NBC who is owned by RCA, a competitor, use E-V microphones in quantity. Another new model is being introduced which should clinch our position and put us into first place in this field, ahead of RCA.

Public Address

For years we have been one of the two leading brands. We are exceptionally strong in the middle and upper price groups. New low priced models are being tooled and will be announced in May 1954. We anticipate that our position will be further enhanced by strengthening the lower cost segment of the line.

Recording

For several years we have produced most of the initial equipment for home tape recorders built in America. Some of these are built to customer’s specifications and case style.

Communications

Although we rank second in this field, we have plans for increasing our sales in this market. We are, however, strong in the aviation industry, supplying microphones to United Air Lines, TWA, Transcanada and smaller lines. We furnish equipment for all Cessna planes.

Special Purpose

The differential noise-canceling microphone has been adapted to many interesting uses wherever high ambient noise is a disturbing factor. The second-order differential has great promise for the future.

Phonograph Cartridges

This is a device that holds the phono needle. It translates mechanical motion to electrical energy. This department is our least profitable one, but carries a great deal of overhead. We are in the process of complete redesign of popular models to effect substantial cost savings, which should reflect next year. Heavy tool expense is being written off this fiscal year.

Currently, we are supplying Zenith at the average rate of 600-1,000 units per day. This line is running smoothly and profitably. Our jobber line is increasing through aggressive merchandising.

High Fidelity Speakers

High fidelity speakers were announced nearly four years ago. This timing, as it coincided with the start of the Hi-Fi boom, was right. Within these four years, we have become one of the two largest producers in the field.

Our expanded line will be announced in May 1954, and will be the most complete line in America. We expect to be the leading line in sales within one year.

Although our sales, in this field, are pointed to sale through distributors, we are suppliers to Admiral, Crosley, Seeburg and Montgomery-Ward.

Public Address Speakers

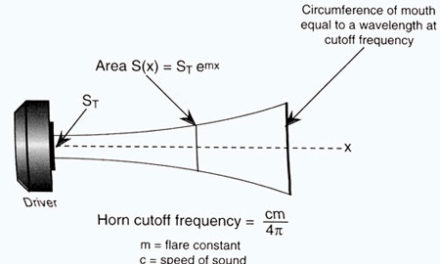

The CDP is a new concept in a two-way PA speaker. Sales have been up to our capacity to produce since its inception. A system employing this principle is being built for the Navy for the Forrestal carrier, which is under construction.

Electronics

For four years, we have produced television boosters, which were completely automatic in operation. Also, UHF converters and boosters have been produced this year. These lines have been quite profitable but not particularly stable. Accordingly, we have watched production and inventory carefully. An F-M booster has just been announced and indications are that it will be successful.

The following is a summary of senior engineering personnel:

Vice President for Engineering: A,M. Wiggins, B.S.E.E. Texas Tech, M.S.E.E. University of Texas. Was formerly employed by RCA Laboratories, Princeton, New Jersey in research on electro-acoustics. Holds a number of patents and has had many scientific papers published. He is a senior member of I.R.E., member of A.S.A., Sigma Xi, AAAS and A.I.P. Length of service, ten years.

Senior Engineer: Carl Moen, B.A., M.Sc., Ph.D. (physics). Formerly associate professor, Pennsylvania State College. Specialist for underwater sound and theory of liquids. Now engaged in research for the Navy. Length of service, two years.

Senior Engineer: Wayne Beaverson, B.S.E.E. and M.S.E.E. University of Notre Dame. Developed second-order differential microphone. Handles administration of government contracts. Heads microphone design department. Length of service, eight years.

Senior Engineer: Norman Friedman, B.A. Physics Washington University. M.S.E.E. University of Iowa. Developed triaxial speaker, super-tweeter, cross-over networks. Length of service, two years.

Chief Engineer: Louis Burroughs. Specialist in microphone miniaturization for TV use. Developed acoustalloy diaphragm material and was co-developer of original differential microphone. Holds several patents. Length of service, twenty-six years.

Senior Engineer: John F. Wood, B.S.E.E. University of Illinois. Heads phonograph cartridge design. Developed new Zenith cartridge, high fidelity ceramic cartridge and many others. Author of several technical articles. Also is doing research on devices relating to magnetic tape reproduction, which have large potential use. Length of service, three years.

Senior Engineer: William Newitt, B.S.E.E., M.I.T. Has done research and development on speaker units. Now engaged in underwater sound research. Length of service, four years.

Senior Engineer: Daniel J. Tomcik, B.S.E.E. and M.S.E.E. University of Notre Dame. Formerly with Hickok Electrical Instrument Company, Cleveland, Ohio. Designed the E-V automatic TV booster, automatic F-M booster, UHF converter, octagonal phono cartridge drive, research on electronically oriented underwater microphone. Length of service, five years.

Senior Engineer: Louis S. Hoodwin, B.S. Physics, Northwestern University. Developed the CDP and Hoodwin Compound Defraction principle of horn sound projection. Heads the Forrestal project. Developed technique for edgewise winding of voice coils. Length of service, four years.

Senior Engineer: Lee Hagey, B.S.E.E. and M.S.E.E. University of Notre Dame. Three years as instructor at Notre Dame. Developed electronic thickness gauge, UHF tuning mechanism, audio pre-amplifier. Length of service, three years.

There are nine additional electronic and electro-acoustical engineers, six model makers and five draftsmen, most of whom are versed in mechanical design. We believe we have an outstanding group of people who have imagination, creative genius, training and genuine interest in commercial aspects of E-V products. Certainly the part that engineering, under the direction of Mr. Wiggins, has played in our solid growth cannot be minimized.

(Editor’s Note: At the time, the E-V engineering department was responsible for 19 patents pending, including the Variable D Gradient Microphone, along with various cartridges, tuners, underwater devices, tape devices, loudspeaker cabinets and horns. Also, 10 patents, largely for microphone technology and accessories, had been issued to the company. Mr. Kahn lists these without specifics.)

Sales Department

The Sales Department, under the direction of Mr. Lawrence LeKashman, Vice President for Sales, is divided into two sections.

Distribution sales account for two-thirds of our volume. We have 1,200 accounts and sell to almost every distributor that we feel meets our standards from the standpoint of credit and ethical operation.

Export has been handled by Rocke International Corporation, New York, for over twenty years.

Broadly speaking, our policy has been to sell and advertise aggressively through the years. Mr. LeKashman, who came to us from RCA, has added impetus, yet keeping within our budget related to sales. We are liberal with respect to returns, adjustments and repair charges.

Jobber sales are under Mr. W.F. Soules, Sales Manager, who has been with E-V since 1945. He holds a B.S.E.E. from the University of Minnesota. Original equipment sales are directed by Mr. Howard Durbin, B.S.E.E. from Purdue University. Mr. Durbin, formerly with RCA, is a competent engineer as well as a salesman and has developed a personal relationship with out original equipment customers. He has been with us seven years.

Mr. George Riley, B.S.R.E. Tri-State College is Sales Administrator, assisting Mr. LeKashman. His length of service is five years.

Sales to jobbers is made through twenty-two commissioned representative organizations in all principle cities with exception of Chicago and the state of Michigan, which we cover with our own salaried people.

Production

Actual production is headed by Mr. Fred Lester, who was formerly General Manager of the Meissner Company. Four department heads report directly to him and the usual chain of management extends down to working group leaders.

Mr. Lester is highly respected as an experienced and efficient manufacturing executive. His assistants are people who have come up through the plant into administrative positions.

Material control is under the direction of Mr. J.N. Grieveson. He has wide experience in the industry, is a capable engineer and has done a fine job in holding inventory at a favorable turnover rate.

Administration

Accounting, coordination of administrative functions, scheduling of production, labor contractual relations and general manager of operations is vested in Mr. Robert Siekman, Executive Vice President. Mr. Siekman joined the company in 1940 when we had fifteen people and carried the manufacturing load during the war years. Our excellent history of labor relations are a tribute to his negotiating skill and the ability to maintain respect and trust of the Union (I.U.E.-C.I.O.)

Mr. Richard Colip, Treasurer, B.S. Indiana University, is in change of general accounting and office functions.

Cost accounting is handled by Mr. Ted Faber, B.S.E.E. Wisconsin. Mr. Faber has had a fine background of production, purchasing and engineering at E-V and has made important contributions in his present position.

We feel sure that our business is in reasonably good balance. If anything, production is lagging behind sales, engineering, and our growth of working capital. Even so, our manufacturing volume will be a million dollars ahead of the last fiscal year when it ends February 28.

Physical Assets

Our fixed asset account is $174,324. An appraisal as of February 28, 1953, made by American Appraisal Company lists the following as cost of reproduction.

Buildings $383,204

Machinery & Equip. 613,290

Cars & Trucks 14,525

Total 1,011,019

This includes railroad sidings which will be abandoned to provide space for construction of a new Plating and Finishing Department. This is valued at $7,029.

The plant consists of approximately 40,000 square feet located on thirteen acres of land within the City of Buchanan.

Intangibles

Engineering cost is traditionally 5 percent of sales. Some of this is recovered through research contracts. However, from 150-200 hundred thousand dollars have been spent annually which has given us our present product excellence, and in addition, a reservoir of commercial ideas from which products of the future will emerge.

Patents are also expensed. Some of these have little value, others a great deal. Some are in the nature of protective patents. Ware are not now in litigation, nor is there the threat of litigation. Several patents in pendency may have immense commercial value.

Good Will

Good will, too, is difficult to measure, except by the growth and acceptability of E-V through the years. Our integrity, financial standing, product design, customer relations and stability are beyond question. Our increase in volume from $714, 000 in 1948 to over $4,000,000 in eight years must mean that people like to do business with us and like our products.

Future Products

We have found strength in diversification. New product lines have added to, rather than detracted from existing items.

Microphones are our product backbone in stability and earnings. They are known the world over to be of first quality and to reflect engineering leadership. We intend to hold and improve, if possible, our position through continued research and product design.

The field includes the following:

Broadcast ant telecast

Public address and paging

Home recording and professional recording

Amateur and point-to-point

Airline and private plane

Taxi, bus and truck

Military and civilian police

Dictating machine equipment

Phonograph cartridges are used by the hundreds of thousands annually. We are tooling a new cartridge which will be mass produced at low cost, which is protected by patents and will sell in high volume. We already have tentative commitments by several of America’s largest users. We further expect to substantially increase our sales in the high fidelity market with the E-V Ultra-Linear Cartridge, which has just been announced.

Loudspeaker research has brought us up to one of the two top producers in the Hi-Fi field. We are introducing several new models which will complete our line. If we can provide production capacity, we anticipate that we will be the leading producer by this time next year.

An Electronic Department was established several years ago. This group has brought forth several interesting commercial items. One of them is an amplifier circuit, conceived by A.M. Wiggins, which has basic features that appear patentable. This amplifier produces superior performance at lower cost of manufacturing than any other circuit now in use.

The amplifier line is in the product development stage and will be produced in our Peoria plant. It will be shown to the trade at the May Show. We anticipate sales in excess of $300,000 our first year. Further, we probably will license several other manufacturers.

The Peoria plant (RME Division) is one which produces communication receivers, but for the past year has concentrated on accessories. We have a new receiver in design, which should have an exceptionally fine sale. Other products are listed in the RME catalogue.

Related Articles:

A Historical Look At EV, With Timeline

Interview: Jim Long On 40-Plus Years With EV